| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SHANDONG MINGHUNG OSB&MDF MACHINERY EQUIPMENT MANUFACTURING CO.,LTD.

Machinery Industrial Park No.0191, Xiao Ge Zhuang Village, Yitang Town, Lanshan District, Linyi City, Shandong Province / / / CHINA

|

Contact Info: +86 187 6990 0191

|

Hall: 6

Stand: 615 C

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

MINGHUNG OSB&MDF Machinery Equipment Manufacture Co., Ltd. located in Xiaogezhuang Industrial Zone, Yitang Town, Lanshan District, Linyi City. The city has a strong foundation for the artificial panel industry and strong innovation capabilities. It is the leading manufacturer of artificial panel machinery and equipment. The important production base is 30km away from Linyi Airport. MINGHUNG Company provides a complete set of process design, electrical design and manufacturing,We can provide one-stop complete factory solutions for wood-based panel customers. MINGHUNG product series include medium density fiberboard (MDF), high density fiberboard (HDF), particle board (PB), oriented strand board (OSB), veneerable super strong particle board (LSB) multi-layer heat press production line, double-sided fixed thickness broadband Sanding machine, gauge saw, mechanical paving machine, air flow paving machine, channel dryer, super screen, post-processing system artificial panel cooling system, turning machine, stacker, storage and transportation trolley. etc. For artificial panel equipment. Mainly involved in particleboard, medium density fiberboard, oriented strand board, multilayer plywood machinery. In addition to providing a complete new brand production line, MINGHUNG is a leading manufacturer of regulating glue and glue mixing systems. It has created many glue blending technologies and promoted them worldwide, and is also a supplier of innovative online and laboratory quality control equipment.

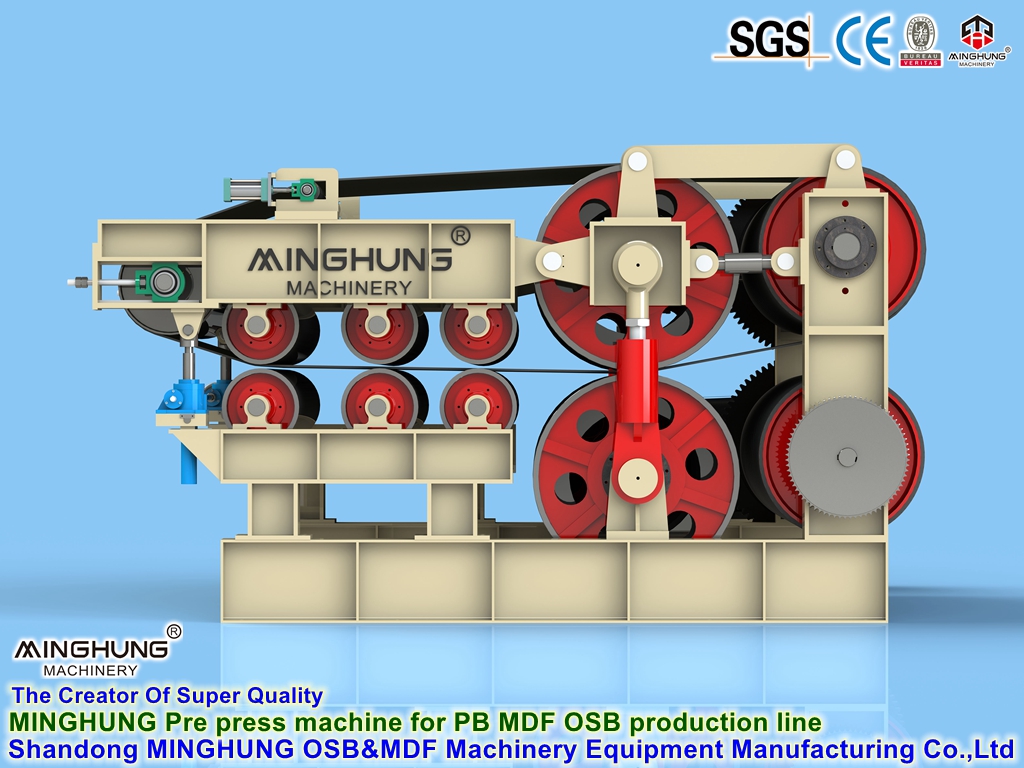

MINGHUNG has become a leader in the field of precision wood-based panel machinery manufacturing. Through its extensive production planning solutions, it is able to produce high-quality particleboards, fiberboards and oriented strand boards, and provides preparation area equipment such as OSB peeling machines, chip roller screens, tube bunle dryer, and super crushers. waste wood cleaning towers, wood shavings super screens, winnowing machines, particleboard mat former machines,OSB mat former,MDF mat former, hot press machine ,pre press machine, auto infeeder for hot press machine, cooling frame for OSB PB MDF , sawing machine line,biomass fuel fields and turnkey projects for the whole plant of artificial panels MINGHUNG supplies equipment including branch material loading devices, drum chippers, long wood chippers, ring chippers, milling machines, hammer crushers and other complete artificial panel preparation section suppliers. The high-capacity particle super chip machine has unique advantages in the global particle board field. The development of the MINGHUNG system proves that Industry 4.0 has come to the field of artificial boards. MINGHUNG has a professional artificial panel technology team. Our technical team has rich and professional artificial panel technology and equipment integration capabilities. It can continuously upgrade and improve existing technologies, continue to research on the development of new product technologies, and can provide Customers are provided with one-stop factory solutions. MINGHUNG company adheres to the service concept of (The Creator Of Super Quality) and will continue to increase investment in research and development, continuously launch new technologies and new products, and create greater value for customers. With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service. Choose us, you need not worry anything, we will help you arrange all. we will offer you the better and suitable machine, two years warranty, professional technical team at your service anytime. and hope that build a good and long-time cooperation.

MINGHUNG has become a leader in the field of precision wood-based panel machinery manufacturing. Through its extensive production planning solutions, it is able to produce high-quality particleboards, fiberboards and oriented strand boards, and provides preparation area equipment such as OSB peeling machines, chip roller screens, tube bunle dryer, and super crushers. waste wood cleaning towers, wood shavings super screens, winnowing machines, particleboard mat former machines,OSB mat former,MDF mat former, hot press machine ,pre press machine, auto infeeder for hot press machine, cooling frame for OSB PB MDF , sawing machine line,biomass fuel fields and turnkey projects for the whole plant of artificial panels MINGHUNG supplies equipment including branch material loading devices, drum chippers, long wood chippers, ring chippers, milling machines, hammer crushers and other complete artificial panel preparation section suppliers. The high-capacity particle super chip machine has unique advantages in the global particle board field. The development of the MINGHUNG system proves that Industry 4.0 has come to the field of artificial boards.

Particleboard is a kind of artificial board made from wood logging and processing residues as raw materials, cut into shavings, dried, glued and hot-pressed. structure:Single layer structure Multi layer structure Directional structure Gradient structure Particleboard production process flow Raw materials-shavings preparation-drying-sorting-glue mixing-paving-prepressing-hot pressing-post-processing-inspection-warehousing 一、 Particleboard production of wood raw materials 1. The low density can increase the compression rate of the board, and the board can obtain higher strength. The density is low and the surface area (specific surface area) of the shavings per unit weight of the raw material is increased, allowing the board to obtain higher bonding strength. At present, mixed raw materials of coniferous and broad-leaf wood are mostly used in production. 2. The bark content is small and the influence of bark on the board is: the bark is dark in color and the board quality is poor (with spots); there are keratin substances in the bark, which affects the strength of the board; the total bark content in production is usually required to be less than 10% , and only used as core layer material. 3. The moisture content should be appropriate Generally, the moisture content is required to be within 40%-60%. If the moisture content is too low, the board will be brittle, and a lot of sawdust will be produced during the preparation of raw materials, which will affect the quality of the board. If the moisture content is too high, drying requires a lot of energy. 二、 Wood shavings preparation shaving shape The geometric shape of the shavings (length, width, thickness and its surface area) has a great influence on the quality of the particle board, among which the thickness has the greatest influence. Generally, the thinner the shavings, the higher the strength of the board. However, shavings that are too thin are prone to fragmentation, making it difficult to ensure the surface quality and strength requirements of the particleboard. When testing the tensile and flexural strength of particleboard, you always want the particles to break within the board rather than being pulled out. Only such a particleboard can exert the maximum wood fiber strength of the shavings. Such an ideal shaving geometry, that is, the length, width and thickness of the shavings, are important process parameters for manufacturing particleboards, and are also the direction pursued by technology and equipment. 三、wood shavings drying Moisture content of wood shavings The moisture content of wood shavings has a great impact on product quality. If the MC is too high, it will not only increase the energy consumption during hot pressing, prolong the hot pressing time, and reduce the efficiency of the hot press, but also affect the bonding ability of the adhesive, reduce the strength, and make the particle board easy to stratify and bubble. If the MC of the shavings is too low, the plasticity of the shavings is reduced, making it difficult to pressurize and compact, which increases the porosity of the shavings; the shavings absorb too much glue and the amount of glue on the surface of the shavings is reduced, which will also reduce the strength of the particleboard. 四、Sorting of wood shavings The purpose of sorting wood shavings Separate qualified and unqualified shavings, remove oversized shavings, wood chips and debris; Separate thick and thin shavings to implement separate gluing of surface and core layer shavings to meet process requirements. 五、Wood shavings mixed with glue Adhesive requirements The molding performance requirements of UF glue: solid content: 60-65%, viscosity: 200-400cp, (25℃) PH value: 7-8, good compatibility with paraffin latex; a certain initial viscosity, enough to make the molding plate The edges of the billet will not collapse during transportation. It is necessary not only to cure quickly

Logs or small-diameter wood are sent to the chipper via a conveyor and cut into wood chips. Stacked in the wood chip warehouse; then sent to the vibrating screen by a belt conveyor for screening. Remove the debris and oversized wood chips (re-crushed for use), and make them uniform in size The wood chips are screened out; and then sent to the water washing or air separation device for water washing or Winnowing removes soil, sand and other impurities from the wood chips; then the wood is The chips are sent to the pre-cooking cylinder for cooking, and the cooked wood chips are sent to the thermal grinder. Defibrate and apply molten paraffin and adhesive (if necessary) Fire retardant materials, preservatives, etc. need to be added); then the separated fibers It is sent to the drying pipe for drying, and the dried fibers are removed through air separation. Thick or agglomerated fibers; qualified fibers are measured by belt conveyor and plate scale After measuring, send it to the paving machine to pave a uniform and flat slab; through the belt The conveyor sends the slab into the hot press for hot pressing. Through temperature, pressure and The precise coordination of time causes the adhesive in the slab to solidify quickly, and the slab is Press molding; the medium density fiberboard coming out of the hot press has a higher temperature and is sent Enter the cooling plate turning machine for cooling; the cooled plates are required according to the length and width specifications. It is required to cut vertically and horizontally, and then perform health care and balancing treatment after cutting, and then proceed Sanding to a certain thickness (according to different production lines, some require curing first and then sanding) and sawing. After the plates are balanced and processed in the storage center, they are sanded and sawed. (Thickness determination and sawing and shaping are carried out in the work section), and finally inspection and classification are carried out. Wait, package and store.

The three-channel dryer uses high-temperature drying and a biomass fuel hot air furnace to automatically dry biomass particles such as shavings drying, fiber drying and other artificial boards, wood particles, etc. It consists of a three-layer cylinder. The materials and hot air are in the dryer cylinder. Go parallel with the flow. Inner cylinder-middle cylinder-outer cylinder. Each layer is equipped with a special-shaped guide plate. The material runs along the spiral guide channel under the action of the rotation of the cylinder and the gravity of the hot air, so that the material can fully exchange heat in the three-layer cylinder. The wet material is pushed into the feeding machine. The material is homogenized by the homogenizer in front of the discharge port of the feeding machine. The material is broken up by the resolver. The loose material is sent to the feeding port through the feeding machine, and then the high-temperature hot air is mixed with the wet material. The materials enter the central cylinder together and rotate, flow along the middle annular channel, turn back again, pass through the outer annular channel, and reach the discharge port of the drying cylinder. The materials in each channel are transported under the pressure of high-temperature airflow and dried in a suspended state. There are also blades in the channels to carry the scattered materials. The tiny particles pass through the dryer at almost the same speed as the air flow. The relatively wet and heavy materials in the middle and outer annular channels fall from the material, but are picked up again by the blades due to the rotation of the drying cylinder, return to the air flow, and are constantly surrounded by the drying medium. The dried material enters the discharge system with the air flow, and the mixed debris is deposited to the sedimentation device for regular discharge. After the material air is separated by the collector, the dry material is discharged from the closed air discharger into the baler bale and discharged from the collector. The exhaust gas is discharged into the atmosphere or recycled.

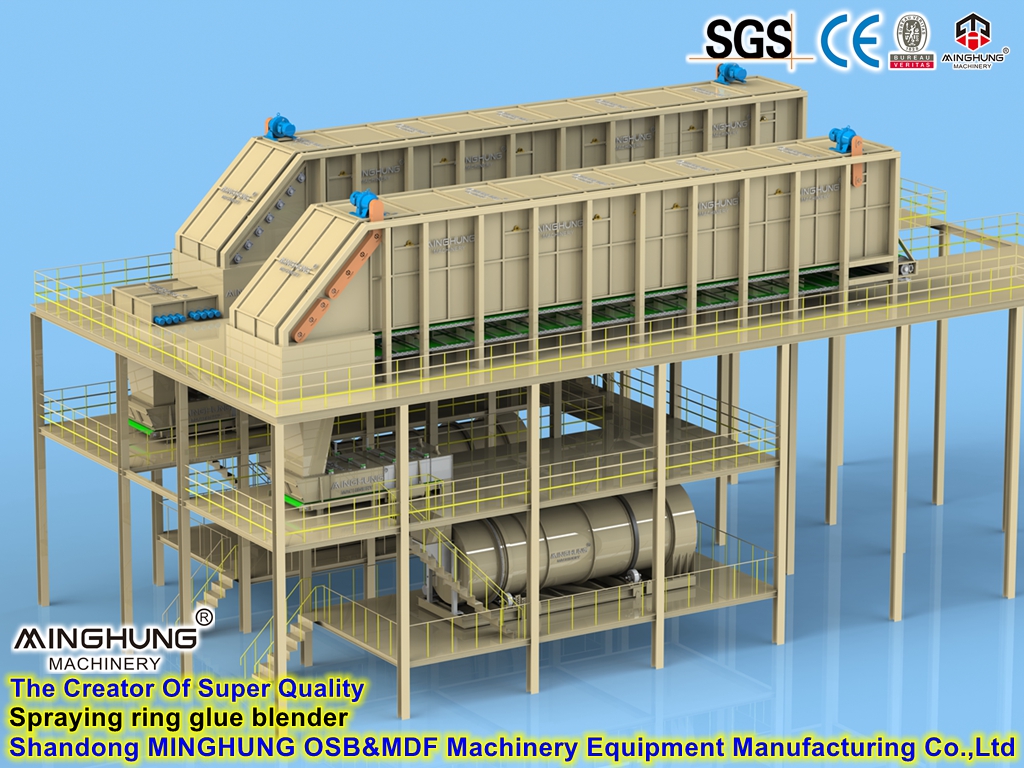

Glue mixing method and glue mixing machine Glue mixing method: ① Friction method: Continuously pour the glue into the stirring shavings, and disperse the glue through the mutual friction between the shavings. It is suitable for mixing glue with small shavings. ②Coating method: Use a sizing roller to apply the glue on the surface of the wood shavings, which is suitable for high-viscosity glue. ③Spray method: The adhesive forms a mist through the nozzle under the action of air pressure (or hydraulic pressure) and is sprayed onto the suspended shavings. Glue mixing machine (1) Ordinary shaving glue mixing equipment ① Spray type continuous glue mixing machine ② Centrifugal spray glue mixing machine ③ High speed glue mixing machine (2) Large shavings glue mixing equipment ① shovel type spray glue mixer ② roller type glue mixer

MINGHUNG has become a leader in the field of precision wood-based panel machinery manufacturing. Through its extensive production planning solutions, it is able to produce high-quality particleboards, fiberboards and oriented strand boards, and provides preparation area equipment such as OSB peeling machines, chip roller screens, tube bunle dryer, and super crushers. waste wood cleaning towers, wood shavings super screens, winnowing machines, particleboard mat former machines,OSB mat former,MDF mat former, hot press machine ,pre press machine, auto infeeder for hot press machine, cooling frame for OSB PB MDF , sawing machine line,biomass fuel fields and turnkey projects for the whole plant of artificial panels MINGHUNG supplies equipment including branch material loading devices, drum chippers, long wood chippers, ring chippers, milling machines, hammer crushers and other complete artificial panel preparation section suppliers. The high-capacity particle super chip machine has unique advantages in the global particle board field. The development of the MINGHUNG system proves that Industry 4.0 has come to the field of artificial boards. MINGHUNG has a professional artificial panel technology team. Our technical team has rich and professional artificial panel technology and equipment integration capabilities. It can continuously upgrade and improve existing technologies, continue to research on the development of new product technologies, and can provide Customers are provided with one-stop factory solutions. MINGHUNG company adheres to the service concept of (The Creator Of Super Quality) and will continue to increase investment in research and development, continuously launch new technologies and new products, and create greater value for customers. With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service. Choose us, you need not worry anything, we will help you arrange all. we will offer you the better and suitable machine, two years warranty, professional technical team at your service anytime. and hope that build a good and long-time cooperation.

How does the temperature inside the slab change when particleboard is hot pressed? The hot pressing time and temperature characteristic curve of the slab directly affects the pressing time and productivity. The total hot pressing time (or hot pressing process) can be divided into five segments in the time-temperature characteristic curve of the core layer. T1: The heat on the hot pressing plate is transferred to the surface wood unit. The surface temperature of the slab close to the hot pressing plate rises rapidly, and the core layer temperature hardly changes. T2: The temperature of the core layer rises rapidly, and the surface wood unit evaporates water. T3: The core temperature rises slowly, and the core wood unit evaporates water. T4: The core layer maintains a constant temperature and water begins to evaporate in large quantities. T5: Continue to heat, the core layer temperature slowly rises, is higher than the boiling point temperature, and approaches the temperature of the hot pressing plate until the hot pressing is completed. What is steam impingement? What does it do? The surface shavings have a high moisture content. When hot-pressed at a high temperature of 150-160°C, steam can be quickly generated and rushed to the core layer. This method is called steam impact method, which can shorten the hot-pressing cycle. What are the commonly used hot pressing curves in particleboard production? (1) Typical hot pressure curve-that is, the relationship between pressure and time during the pressurization period. From T1 to T7 is a hot pressing cycle, and from T2 to T6 is called hot pressing time. The hot pressing pressure usually referred to in the process refers to the maximum pressure Pmax per unit area of the slab. T1: The time when the slab is fed into the press and the slab is not under pressure. T2: The hot press plate is closed from the beginning until it is fully closed, and the slab is still under pressure. T3: After the upper and lower hot pressing plates press the slab, the pressure rises to the working pressure Pmax. T4: Pressure holding time, the slab is pressed tightly and the adhesive solidifies. This period of time accounts for most of the entire hot pressing time. T5: After the adhesive has cured, the pressure drops to zero. T6: The time from when the pressure is zero to when the hot plate is fully opened. T7: Unloading time. (2) Hot pressing curve using thickness gauge In particle board production, thickness gauges are often used to check the final thickness of the board. After the hot press plate is closed, the plate is pressed to the thickness of the thickness gauge. Only part of the pressure is pressed on the plate and most of the pressure falls on the thickness gauge. However, during this process, the pressure does not decrease in any way caused by the Hot press. In the actual test, after the pressure reaches the maximum value, it immediately accelerates it drops somewhat and there is no pressure maintenance phase. (3) Commonly used hot pressing curves Various hot pressing curves can be used in particle board production according to changes in process conditions, such as three-stage pressure reduction curves, multi-stage pressure reduction curves and zero-stage pressure retention curves (when the hot pressing pressure decreases). The pressure plate is not opened until it approaches zero, but is left for a while to release the steam in the plate to prevent bubbling, delamination, etc.

MINGHUNG supplies equipment including branch material loading devices, drum chippers, long wood chippers, ring chippers, milling machines, hammer crushers and other complete artificial panel preparation section suppliers. The high-capacity particle super chip machine has unique advantages in the global particle board field. The development of the MINGHUNG system proves that Industry 4.0 has come to the field of artificial boards. MINGHUNG has a professional artificial panel technology team. Our technical team has rich and professional artificial panel technology and equipment integration capabilities. It can continuously upgrade and improve existing technologies, continue to research on the development of new product technologies, and can provide Customers are provided with one-stop factory solutions. MINGHUNG company adheres to the service concept of (The Creator Of Super Quality) and will continue to increase investment in research and development, continuously launch new technologies and new products, and create greater value for customers. With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service. Choose us, you need not worry anything, we will help you arrange all. we will offer you the better and suitable machine, two years warranty, professional technical team at your service anytime. and hope that build a good and long-time cooperation.

OSB PB MDF production line manufacturer

No represented companies found.

The company has no registered brand information.

TR

TR