| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SHANDONG MINGHUNG WOOD MACHINERY CO.,LTD

Machinery Industrial Park No.0191, Xiao Ge Zhuang Village, Yitang Town, Lanshan District, Linyi City, Shandong Province / / linyi / CHINA

|

Contact Info: +86 187 6990 0191

|

Hall: 6

Stand: 607 B-3

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

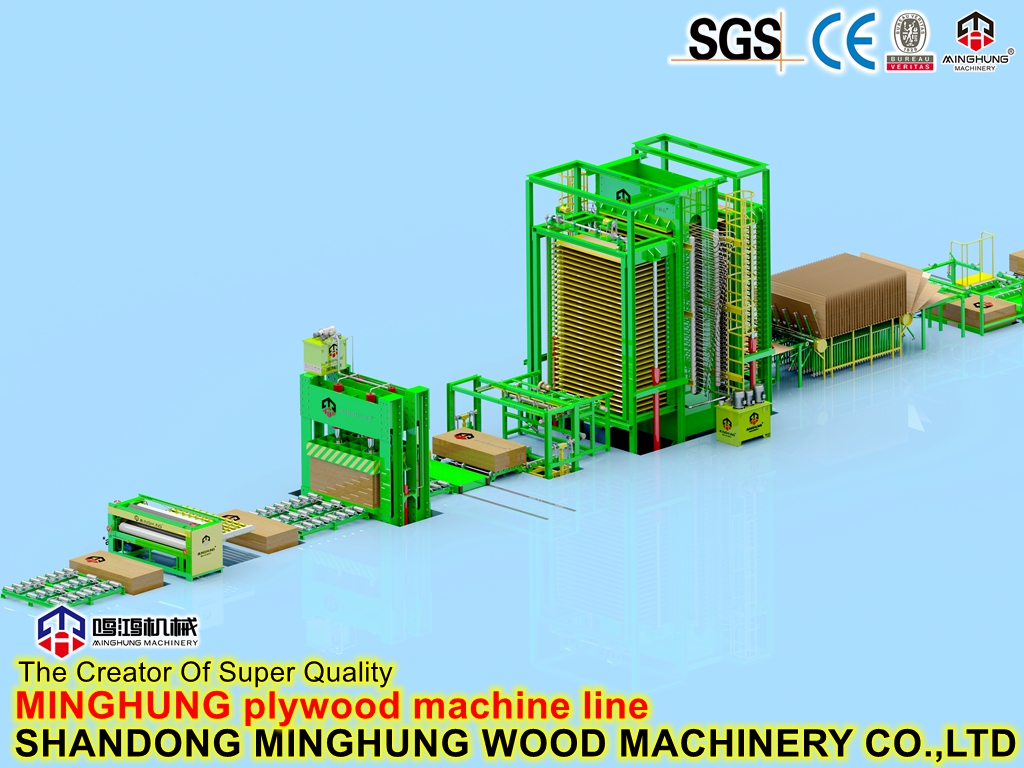

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city. Our products have acquired EU CE, ISO 9001, ISO 14001, CCEP, and Energy Conservation Certification. Our company integrates design, research and development, production and sales, and works closely with China s advanced scientific research institutions. We have a strong research and development team, at present, our machinery has won a number of national patents. Pay more attention to machine details, details determine sucess or failure, so we continuous improve and optimize machines performance, strictly control each production step, using advanced lathe processing machine, and through many times inspections, make sure our machine accurate and durable. Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback. Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, 400tons 500tons 800tons plywood cold press machine, 500tons 600tons 800tons 1200tons 10layer 15layer 20layer 25layer plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line,plywood cutting machine,lift table, sanding machine. With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service. Choose us, you need not worry anything, we will help you arrange all.

Our product 4feet Veneer production line includes 4feet log debarker, 4feet wood peeling machine, log conveyor, and 4feet vacuum veneer stacker. The function of veneer peeling line for processing wood and produce wood veneer, as you know, wood veneer is material for making plywood, wooden furniture and others. So its quality are very important. This requires the veneer machine are good quality and strong enough. This 4feet veneer production line can process max log length 1400mm, and max log diameter 550mm, and thickness can be 0.5-4mm. With advanced and mature production technology, and experienced workers and professional technicians, So our veneer machine structure and characters are good. And we use good and thick materials, super machine accessories, good electric box and upgraded electric parts, So our log peeling machine are strong enough to peel kinds of hardwood like beech, birch and others, and can help you produce very accurate wood veneer with smooth surface, which will help you create much value. Welcome contact us for more information of veneer machine, we will offer machine working video and details for you.

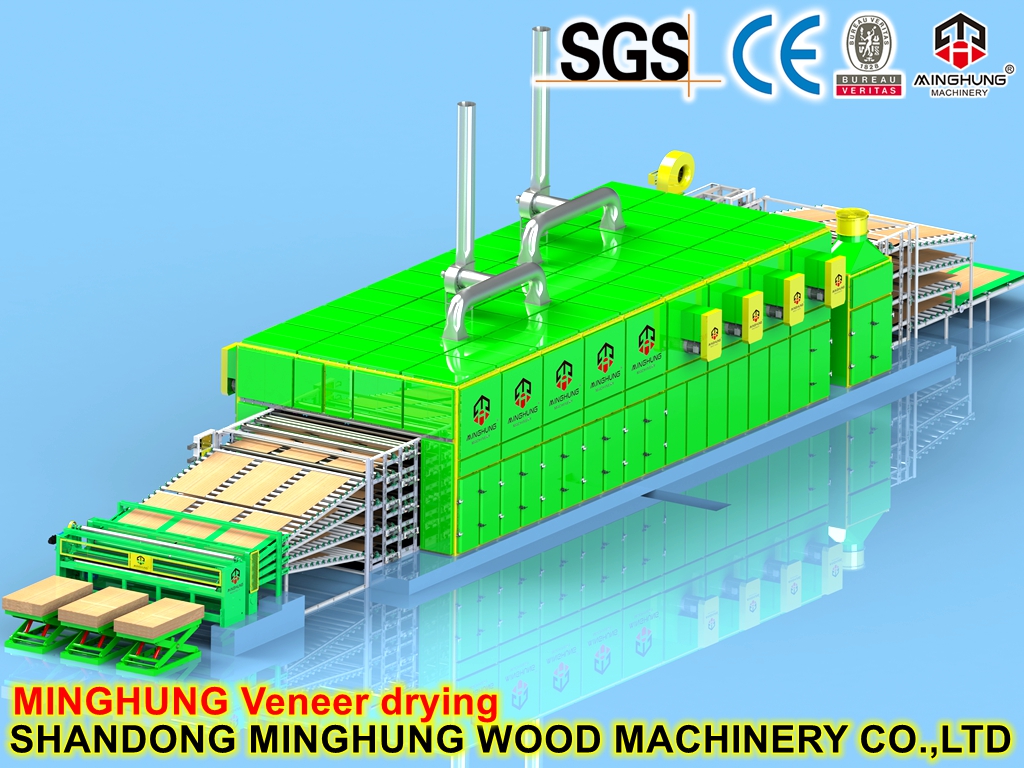

Veneer dryer The veneer (plywood) dryer can be divided into three heating forms: hot air heating, steam heating, and heat transfer oil heating according to different heating forms. According to different fuels, it can be divided into fuel oil, gas, coal, firewood, and electricity. The equipment can be divided into manual loading and automatic loading. The veneer enters the dryer, and according to the set value, the temperature and humidity in the dryer are automatically controlled, so that the drying material can be leveled and the moisture can be controlled uniformly. The equipment can determine the size of the equipment according to the user s output, and it can be divided into automatic board and manual board. This equipment has large output, high degree of automation, low cost of use, uniform drying, and good effect. Through drying, it can avoid mildew and blue change of plates in high temperature and high humidity environment (such as eucalyptus wood, rubber wood, poplar, camphor It is ideal in the field of veneer processing, flame retardant veneer production, plywood production, flame retardant plywood production, and dyed veneer (board) production. Veneer drying equipment. product description Product advantages: This equipment has a high degree of automation, low operating cost, small footprint, and can be operated 24 hours a day, saving labor, and the annual labor cost saving can reach 150,000 US dollars. Obvious features: 1. High degree of automation, automatic loading, labor saving, automatic heating, dehumidification, high drying intensity, long drying time, high moisture saturation, and energy saving. 2. Dry evenly. The peeled veneer undergoes heat exchange and moisture removal in multiple sections, and after drying for about 1.5 hours, the moisture content is low and uniform, which can meet the production needs of veneer and plywood. 3. The output is large. According to the needs of different users and different materials, the output of the equipment can reach 1-5 cubic meters/H. 4. The equipment adopts fin-type heating device, which has large heat exchange area, fast temperature increase, large circulating air volume, many cycles, high heat exchange efficiency, high exhaust water saturation, energy saving, and low use cost, which is better than roller type veneer. The drying equipment saves energy by more than 40% (the roller adopts the air spray method, the contact time between the hot air and the plate is short, and the heat exchange efficiency is low). 5. A piece of equipment investment can be used for more than ten years, super cost-effective 6. The failure rate is low, the network belt is worn, and the network is disconnected, and the failure rate of the pallet is low. 7. The equipment adopts vertical plate loading and drying. The operation time of the plate skin in the equipment is long, which can reach 1-2 hours. The temperature can be controlled according to the section. 13-15min, the folding type veneer dryer has large output, low energy consumption and low drying cost.

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, 400tons 500tons 800tons plywood cold press machine, 500tons 600tons 800tons 1200tons 10layer 15layer 20layer 25layer plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line,plywood cutting machine,lift table, sanding machine.

Our product Hot press machine for pressing glued plywood, make it become one solid, strong and good quality board. Hot press machine are very important for plywood quality. Hot press machine can be different pressure and floors, for example, it can be 20floors. 15floors, 10floors or others as you want, and its pressure can be 500ton, 600ton, 800ton or others as you want. And if your plywood size are bigger or smaller, do not worry, we can customized our machine for you. MINGHUNG MACHINERY hot press machine use thick material, total weight are heavy and strong; using good quality oil cylinders and mature hydraulic station and system, using Siemens motors and cnc screen and Schneider electric parts; using good quality and solid hot plates; Therefore, our hot press machine s life span are longer, and its working performance will be very good for help you produce good quality plywood. Welcome contact us for more information of plywood hot press machine.

Blet veneer drying Veneer drying is very important for the production of plywood. After wood is produced into veneer through veneer lathe, the moisture content is 50-70%. Plywood production requires veneer moisture content of 8-%14. The moisture content of veneer is greater than %14, which brings negative The influences are: 1. It will increase the hot pressing time of the plywood blank in the hot press. The heating of the hot press is heated by a steam boiler or a heat transfer oil boiler. If the hot pressing time is increased, it is equivalent to an increase in heat loss. 2. If the moisture content is higher than %14, the veneer after glue spreading will seep out of glue during the hot pressing process, causing the plywood to crack. 3. If the moisture content of the veneer is 14%, the plywood blank needs to be dehumidified several times during the hot pressing process to remove the moisture inside the plywood blank. If the temperature is not properly controlled, there will be air bubbles in the semi-finished plywood, which will crack and cause the plywood to be scrapped. MINGHUNG veneer drying effectively solves the problem of veneer drier, veneer drying, according to the density of different veneers, the customer s different veneer output, the factors of purchasing cost, MINGHUNG has developed a variety of veneer drying types MH-RD40L、MH-RD304HL / MH-2830L / MH-MD3618 : roller veneer dryer, wire veneer dryer, mesh veneer drier, press drying, square tube veneer drying, Hollow veneer drier, ect specialized in research on saving energy, energy consumption and improving production efficiency of veneer drying.

Our product Roller veneer dryer for drying original wood veneer, remove abundant humidity, in the end, the wood veneer humidity will be 5%-10%, so it is suitable for making plywood. Veneer roller dryer are suitable for big drying capacity per day, it can be different length, width and floors. For example, some our clients choose width 4500mm, length 32meters, and four floors, and this big roller dryer can drying 100m3 per day. Our roller dryer use very thick material for frame and doors, so its weight are heavy a lot; use unique air flue and big fans to increase the production capacity; and use Siemens motor to make sure good quality and powerful energy; even the very small parts like the bearings, we insist choosing the good quality; and each kinds of parts have their own models, so before loading, we will packed each of them and make Marks, so when roller dryer reaches your factory, it is easy for you to know what are they. Roller dryer includes many different parts, so the production technology and worker rich experience are important, and our factory with this advantage. Choosing our roller dryer, you can use many years with good performance. Welcome contact us for more information, we will offer the suitable dryer for you according to your own conditions and requires.

Our product Cold press machine for pre-pressing plywood, so it first makes glued plywood fixed, thus can easy put plywood into hot press machine. Usually, cold press machine s pressure can be 400ton, 500ton and 600ton, for standard plywood size 4 8feet, 500ton cold press are good and enough. For 500ton plywood cold press machine, we use thick material for making frame; using two good main oil cylinders, and with fast lifting cylinders; with Siemens brand motors and parts; with mature hydraulic station and system; Therefore, our cold press machine are strong and good quality. The operation of plywood cold press also very easy, just put plywood into machine, and press the button, cold press will be start work. Welcome contact us for more information about cold press machine.

flim yüzlü kontrplak sıcak pres makinesi

plywood roller sawing machine

veneer peeling machine line

No represented companies found.

The company has no registered brand information.

TR

TR